Wind Turbine Main Shaft Brake: Frictional forces

While the rotation of the rotor of the wind turbine can be slowed by changing the pitch angle of the blades during aerodynamic braking, the rotor needs a mechanical main shaft brake to keep it stopped completely.

Frictional force is an essential physics concept that will help explain the working mechanism of the main shaft brake, and its maintenance implications.

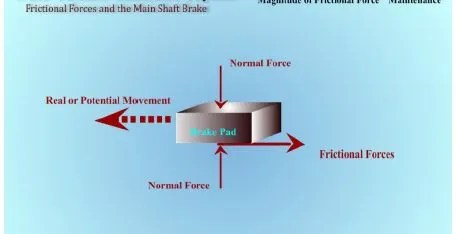

Frictional forces exist between two solid materials at their contacting interface. The forces act in the opposite direction to any real or potential movement tangential to the contacting surface between the two solid materials.

The maximum magnitude of the frictional force that is available to keep the main shaft stopped is directly proportional to the force that pushes the brake pads against the brake disk. This force acts perpendicular to the contacting surface between the brake disk and the brake pad.

The contacting surfaces are full of microscopic peaks and valleys due to the roughness of the materials, and the more these surfaces are squeezed together, the more difficult it is to overcome the peaks and valleys to achieve any real movement along the contacting surfaces.

The height of the microscopic peaks and valleys determines the roughness of the contacting surfaces, as well as the value of the coefficient of friction.

This coefficient is an important concept in the maximum friction law in physics. The value of the coefficient of friction for any two contacting solids is obtained through lab experiments.

The value of the coefficient of friction also depends on the mechanical properties of the two contacting solids, since the strength of the materials will determine whether the peaks and valleys will be overcome or simply sheared away and filled up to achieve the movement.

If the peaks are sheared off and the valleys filled in, the roughness of the contacting surface will vary unpredictably and cause the brake to be less effective or fail completely.

In the worst case, this process may generate excessive heat and weld the two solid materials to each other, locking the main shaft and causing extensive damage to the brake system. This scenario is most likely if the frictional brake is applied before the main shaft speed has been sufficiently reduced by the aerodynamic brake.

The maximum friction law in physics applies to dry friction only. Contamination of the friction surfaces by grease, oil, or other fluids should be prevented and monitored during inspection and maintenance.

Highland Community College as part of WindTechTV.org